Product Info

This is where you can show off your modelling expertise. You can simply email me photos of your photos that you have taken of the products you have purchased and added to your layout or diorama, let me know what information you want me to add along with the pictures and they will be displayed in this page.

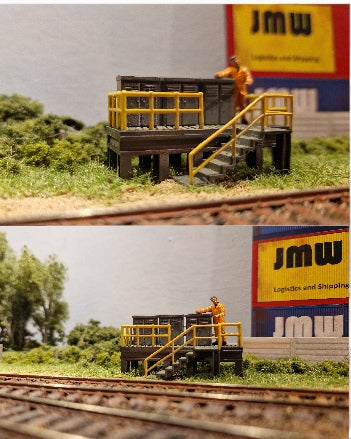

John Wright

This Platform cabinet was bought by customer John Wright along with a few other items from our stall at the Model Rail Crewe show recently.

John kindly submitted these photos and agreed to us displaying here.

I think you will agree that John did a fibne job in painting these and displayoing them on his layout.

Product Info.

Lineside Control Cabinet Platforms.

Available in single steps with the steps going up to the right or up to the left. Also a double version with steps front and back , being longer with more cabinets.

Product is available in OO, TT and N gauges.

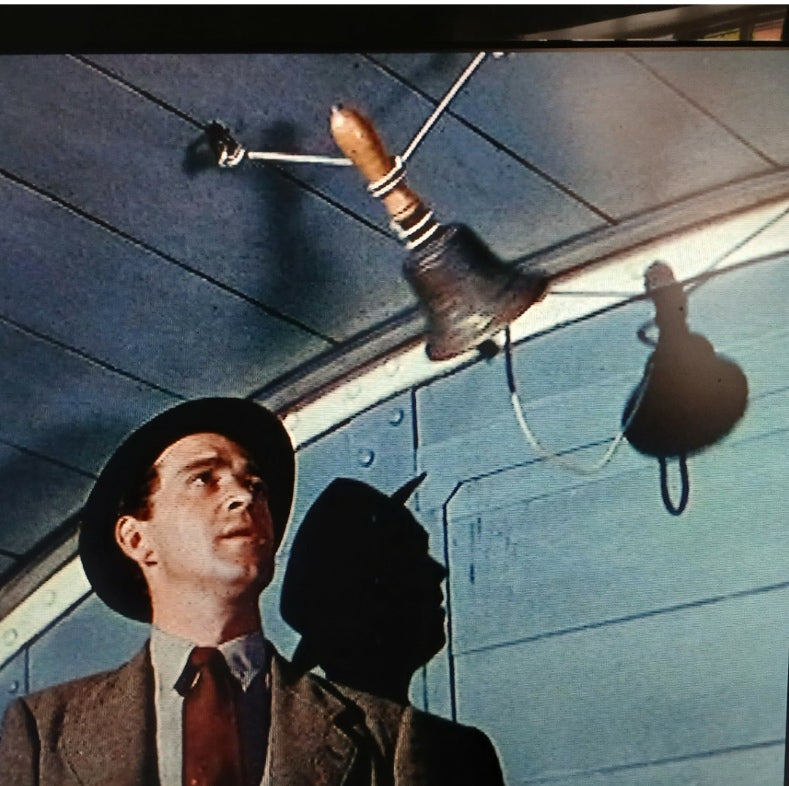

Titfield Thunderbolt Bell, bespoke part for Richard Swiderski

I was asked by Richard to produce something for his Rapido Titfiled Thunderbolt Model. True to my self I thought one of those big bells like on the front of the American steam engines should not be a problem! Richard sent me a couple of photos, one of which shown here

What I came up with....

This is what I came up with, I made a few samples thinking that being so tiny it would not print the fine detail and the strings holding up the bell, but to my surprise they printed just fine. I ten tried painting one and removing from the fine supports, this would show if it would survive removal. In this case it did but it was a tedious jiob. By the way, the ruler marks are millimeters!

Even i am taken by surprise

Richards model finished

So here is Richards fine handywork fitting the bell into the Brake Van, just like the real thing. I have to truly admit that this looks far better than I envisaged. Thanks to Richards input this item far exceeds my expectations and shows what can be acheived with a bit of effort.

Top photo is a film clip and is the copyright of the film maker, Bottom photo includes the Brake Van from Rapido's Titfield Thunderbolt model.

If you wish to have bespoke items made please contact us from our contact page.